Precise Metal Prototyping

If you’re looking to bring a concept from a sketchbook to a real-world, rugged metal piece, you need robust prototyping services to bridge the gap. That’s where Elite Welding & Fabrication can help, with our dedicated metal prototyping capabilities. Our prototyping processes are designed to handle everything from early-stage ideas to one-of-a-kind custom projects!

Where Metal Prototyping Matters

Prototyping metal doesn’t just serve as a “first version” of a part. It lets you test the feasibility of your design, fit, form, and function–all while catching issues long before you’re locked into a full-scale production run. With the right prototyping partner, this process can save you time, money, cost, and materials, all while providing a tangible model that helps align engineers and designers.

In industries where margins, weight, or precision matter, prototyping isn’t optional: it’s essential. A flawed part in final production can cost more than investing in a functional prototype early. With their experience and equipment, Elite Welding & Fabrication uses prototyping as a strategic step, not a glorified mock-up. This bridges creative imagination and industrial execution.

Elite Welding & Fabrication’s Approach

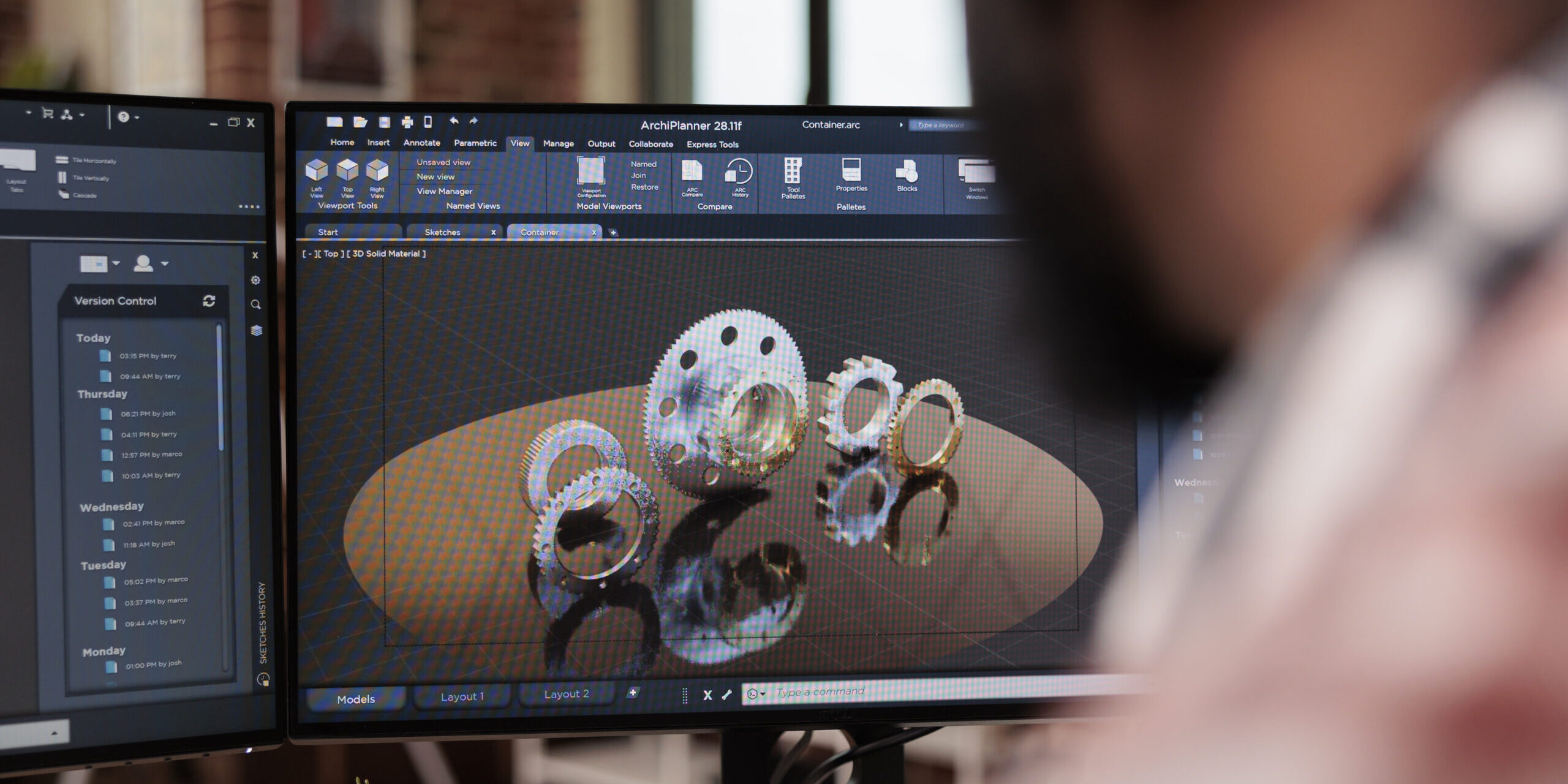

Elite Welding & Fabrication emphasizes flexibility and experience. Whether you arrive with rough sketches, a full engineering drawing, or just a brainstorm, our team is ready to step in and turn that into a real metal prototype. We handle both the design/planning phase and the fabrication phase, from idea to final build. Our equipment suite spans metal-cutting, forming, welding, and more. We understand that many challenges in prototyping stem from the transition from concept to final product. By leveraging our full-scope experience, we help our partners navigate the prototyping process from start to finish.

One of Elite Welding & Fabrication’s biggest advantages is our willingness to invest in our partner’s knowledge. We don’t just stop at building a prototype–we communicate about the options, the trade-offs in materials, finishes, fabrication costs, and lead times. This means you remain in control of major decisions, rather than being a passive recipient of unclear choices and long delays. This willingness to explain choices helps our partners make informed decisions for not only the prototyping stage, but for downstream production long into the future.

Investing In Prototyping

If you are developing a new product, building a custom metal job, or want to test how your design will fare in real applications, our prototyping service is set up to support you. Our team will help you refine the concept, build it in metal, iterate upon it as needed and deliver a version that reflects what the final product should look like. Our goal is not just a metal sample, but a refined proof point: one that minimizes surprises later and builds accurate expectations. For projects where metal matters, prototyping with someone who understands both design and fabrication is a difference maker. Work with Elite Welding & Fabrication for your prototyping needs and see how much the difference matters.